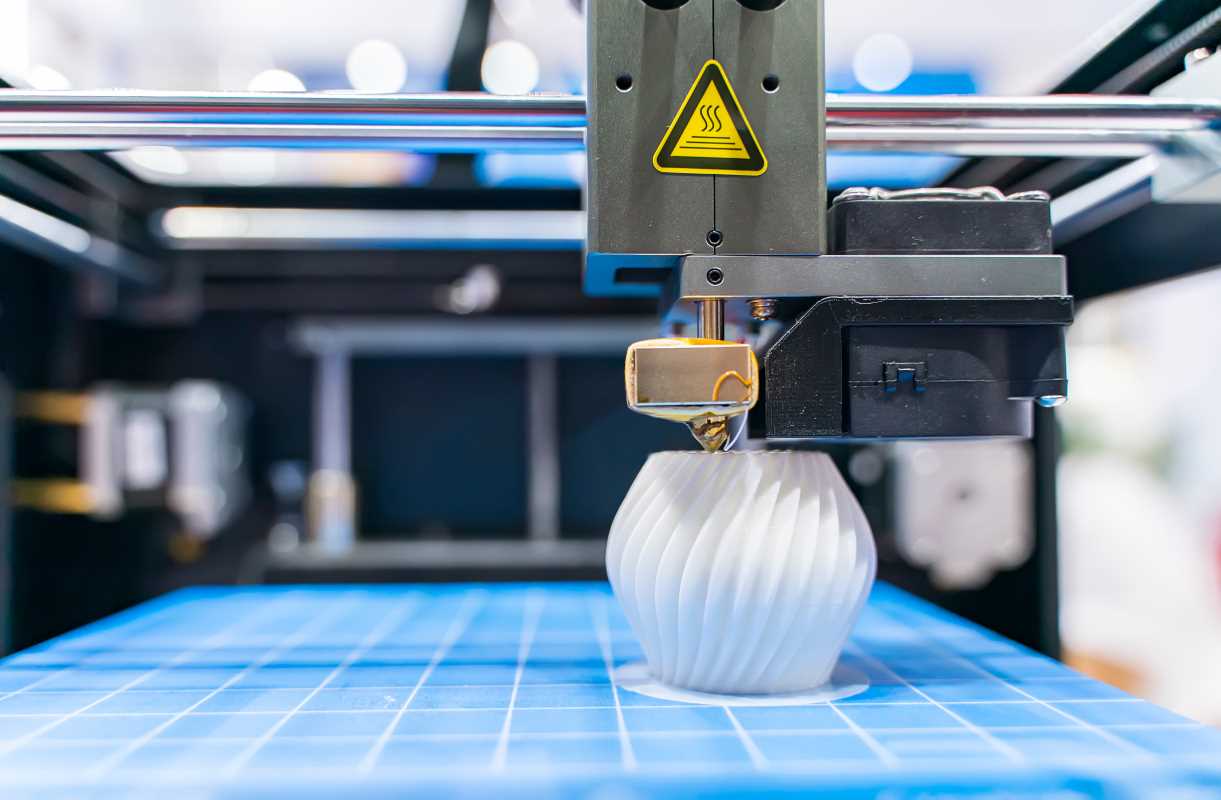

3D printing, also known as additive manufacturing, is revolutionizing the product manufacturing landscape by offering unprecedented flexibility, efficiency, and innovation. Unlike traditional manufacturing processes, which typically involve subtracting material from a larger block or using molds to shape products, 3D printing builds objects layer by layer from digital designs. This transformative technology is reshaping industries and redefining how we think about production, supply chains, and sustainability.

The Basics of 3D Printing

At its core, 3D printing involves creating three-dimensional objects from a digital model. The process begins with a computer-aided design (CAD) file, which provides the blueprint for the object. The printer then deposits material layer by layer, following the digital instructions. There are various types of 3D printing technologies, including:

- Fused Deposition Modeling (FDM): Melts and deposits plastic filament layer by layer.

- Stereolithography (SLA): Uses ultraviolet light to solidify liquid resin.

- Selective Laser Sintering (SLS): Fuses powdered materials, such as plastic or metal, with a laser.

- Metal Additive Manufacturing: Involves sintering or melting metal powders to create durable components.

Each method caters to specific applications, materials, and industries, making 3D printing versatile across diverse manufacturing needs.

Customization and Personalization

One of the most significant advantages of 3D printing is its ability to produce highly customized and personalized products. Traditional manufacturing often relies on mass production to achieve economies of scale, which can limit the ability to tailor products to individual needs.

- Healthcare Innovations

- 3D printing has been instrumental in creating personalized medical devices such as prosthetics, orthotics, and dental implants. By using patient-specific data from imaging technologies, healthcare providers can design devices that fit perfectly, improving comfort and functionality.

- Consumer Goods

- Companies are leveraging 3D printing to offer personalized products, such as custom-fit footwear, eyewear, and jewelry. Consumers can now enjoy products designed to match their preferences and measurements precisely.

- Automotive and Aerospace

- Custom components for vehicles and aircraft can be produced on demand, reducing the need for large inventories and allowing for rapid prototyping during the design phase.

Streamlining Prototyping and Design

Traditionally, developing a prototype could take weeks or months and require significant resources. 3D printing has dramatically reduced these timelines, accelerating innovation.

- Rapid Prototyping

- With 3D printing, designers can create prototypes quickly and affordably, allowing them to test multiple iterations before finalizing a design. This agility enables companies to bring products to market faster.

- Complex Geometries

- 3D printing allows for the creation of intricate designs and complex geometries that are impossible or expensive to achieve with traditional manufacturing methods. This capability has expanded the boundaries of what can be engineered and produced.

- Design Freedom

- The layer-by-layer approach of 3D printing removes many constraints associated with traditional manufacturing. Designers can focus on functionality and aesthetics without being limited by tooling or machining processes.

Reducing Waste and Enhancing Sustainability

Sustainability is a growing concern in modern manufacturing, and 3D printing offers solutions to reduce environmental impact.

- Material Efficiency

- Traditional manufacturing often generates significant waste, as excess material is removed during machining. In contrast, 3D printing uses only the material required to build the object, minimizing waste.

- Localized Production

- 3D printing enables localized manufacturing, reducing the need for long-distance shipping and the associated carbon footprint. Companies can produce goods closer to their consumers, enhancing supply chain efficiency.

- Recyclable Materials

- Many 3D printing processes use recyclable materials, and innovations in biodegradable filaments and resins are further improving the technology's environmental credentials.

- On-Demand Manufacturing

- By producing items only when needed, 3D printing eliminates the need for large inventories, reducing waste from unsold products and overproduction.

Transforming Supply Chains

3D printing is reshaping supply chains by reducing reliance on traditional manufacturing hubs and enabling decentralized production.

- On-Demand Production

- With 3D printing, companies can produce parts and products as needed, reducing storage costs and the risk of inventory obsolescence.

- Distributed Manufacturing

- Decentralized manufacturing allows companies to establish smaller production facilities closer to their customers. This reduces transportation costs, shortens delivery times, and enhances responsiveness to local demand.

- Supply Chain Resilience

- 3D printing enhances supply chain resilience during disruptions such as pandemics, natural disasters, and geopolitical conflicts by enabling local production of critical components.

Advancements in Materials

The evolution of 3D printing materials has significantly expanded its applications across industries.

- High-Performance Polymers

- Advanced polymers are now available for 3D printing, offering properties such as heat resistance, durability, and flexibility. These materials are widely used in automotive, aerospace, and medical applications.

- Metal Additive Manufacturing

- Metal 3D printing is transforming industries that require strong and lightweight components, such as aerospace and defense. Titanium, aluminum, and stainless steel are commonly used in this process.

- Bioprinting

- Bioprinting involves using bio-compatible materials to create tissue structures for medical research and potential organ transplantation. This cutting-edge technology holds promise for addressing organ shortages and advancing regenerative medicine.

- Composite Materials

- 3D printing with composite materials, such as carbon fiber-reinforced polymers, offers enhanced strength-to-weight ratios, making them ideal for applications in high-performance industries.

Challenges and Future Directions

While 3D printing offers numerous advantages, it also faces challenges that need to be addressed for widespread adoption.

- Cost and Speed

- Despite advancements, 3D printing can still be slower and more expensive than traditional manufacturing for large-scale production. Ongoing research aims to develop faster and more cost-effective printing technologies.

- Material Limitations

- Not all materials are suitable for 3D printing, and the range of available materials is still limited compared to traditional manufacturing. Innovations in material science are expected to address this gap.

- Regulatory and Quality Assurance

- Ensuring the quality and safety of 3D-printed products, especially in critical industries such as healthcare and aerospace, requires standardized regulations and rigorous testing protocols.

- Skill Gaps

- Adopting 3D printing technology requires specialized knowledge and training. Bridging the skill gap through education and workforce development is essential for broader implementation.

3D printing is redefining product manufacturing by offering unparalleled customization, streamlining prototyping, and transforming supply chains. Its potential to reduce waste, enhance sustainability, and drive innovation across industries makes it a cornerstone of the future of manufacturing. While challenges remain, ongoing advancements in technology, materials, and processes are paving the way for broader adoption and integration into traditional manufacturing systems.

As 3D printing continues to evolve, its impact on industries such as healthcare, aerospace, automotive, and consumer goods will become even more profound. By embracing this transformative technology, manufacturers can unlock new possibilities, drive efficiency, and contribute to a more sustainable and innovative future.